Compact Heat Exchanger and Compact Heat Exchange Reactor

CompRex Compact Heat Exchangers and Compact Heat Exchanger Reactors are custom designed for a wide range of chemical processes, oil and natural gas processing, industrial gas and power generation applications where efficient heat transfer and compact size are often critical.

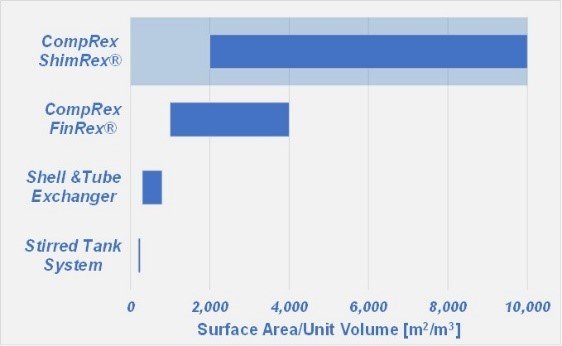

ShimRex® is one of CompRex’s main product lines of compact heat exchangers and compact heat exchanger reactors. It is manufactured using diffusion bonded technology. The alternating layers of heat transfer streams allow for efficient heat transfer. Channel sizes have hydraulic diameters less than 3 mm, so heat travels short distances and the surface area-to-volume ratio of the unit is one of the highest in the industry.

ShimRex units are manufactured by photochemical etching the internal heat transfer surface and structure into sheets of metal that are then stacked in a pattern and diffusion bonded into a single block. CompRex uses a patented technology to provide customized internal heat transfer surfaces that provide the thermal and hydraulic performance required for each particular application.

Advantages of ShimRex Heat Exchanger

Custom design for exact client needs

Very high temperature and pressure applications

Internal ligaments for increased mixing and even higher heat transfer

Tight approach temperatures (less than 2F for some applications)

Relatively low pressure drop

Extremely high surface area-to-volume ratio

Compactness

Applications of ShimRex Heat Exchanger

Aerospace industry

Marine

Cryogenics

Power industry

sCO2 Brayton Cycle

Hydrogen production

Solar industry

Fuel Cells

Advantages of ShimRex Reactor

High temperature/high pressure reactions

Small catalyst particles packing for high catalyst utilization (up to 5x)

Intermittent injection within the reactor block

No liquid catalyst premixing prior to reactor

Intermittent reactant injection for higher selectivity and productivity

Tight temperature control

Highly exothermic or endothermic reactions

Sensitive catalyst or product

Higher yields of desired products

Compact design

Smaller footprint and auxiliary equipment

Lower catalyst requirements

Applications of ShimRex Reactor

Gas-to-Liquid processes

Partial oxidation reactions

Hydrogenation

Polymerization

Petrochemical processes

Hydrogen production

Fuel Cells

Construction Materials

The ShimRex exchangers and reactors can be manufactured out of a variety of metals and alloys. Choice of construction material is dependent on application conditions, such as temperature, pressure and fluid properties. Materials include:

Stainless Steel

Titanium

Aluminum

Super alloys (for extreme temperature and pressure applications)

Including 617 and 740H

Copper

Fabrication Process

ShimRex products are manufactured by photochemical etching of metal sheets to the desired internal shapes of the unit. The thin sheets are stacked and heated at high temperatures under intense pressures until the metal sheets are bonded into a single block of metal. The ShimRex manufacturing process results in units that can withstand severe operating conditions.