CompRex announced today its selection for the 2020 TechConnect Defense Innovation Award based on its compact heat exchanger and heat exchanger reactor technologies.

Entering its seventh year, the annual Defense TechConnect (DTC) Summit brings together defense, private industry, federal agency, and academic leadership to accelerate state-of-the-art technology solutions that will strengthen national security. The TechConnect Defense Innovation Award recognizes the top 15% of submitted technologies as ranked by a selection committee based on the technology’s potential positive impact.

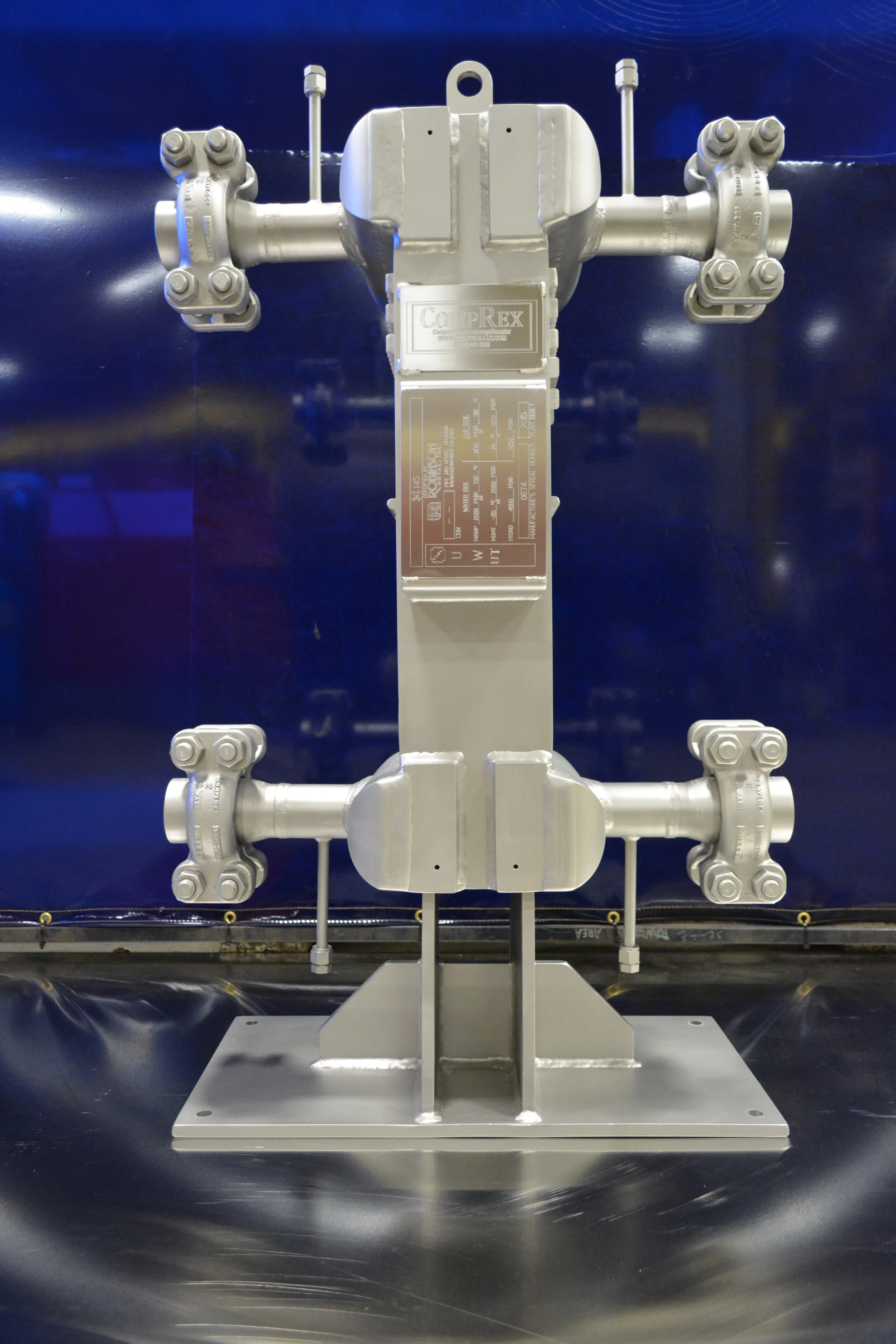

Today, CompRex, LLC held the ribbon cutting ceremony for its new facility located at the Coulee Region Business Center (CRBC) in La Crosse, Wisconsin. This location will serve as CompRex’s new headquarter and features state-of-the-art manufacturing equipment allowing the production and testing of highly advanced brazed and diffusion bonded compact heat exchangers and heat exchanger reactors.

CompRex worked closely with the City of La Crosse through the La Crosse Area Development Corporation and the CRBC to achieve this new milestone in the young company’s growth.

CompRex announced today that it was awarded a $1.76 million project from the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E). The funding, through the High Intensity Thermal Exchange through Materials and Manufacturing Process (HITEMMP) program, will be used to develop new approaches and technologies for the design and manufacture of high temperature, high pressure, and highly compact heat exchangers and components.

CompRex, LLC, a Wisconsin-based small business that specializes in the provision of compact heat exchanger and reactor solutions, announced that it has received a $1.2 million award from the U.S. Department of Energy Solar Energy Technologies Office(SETO) to advance concentrating solar-thermal power (CSP) research and development.

Eight innovative small businesses in Wisconsin will receive matching grants to commercialize their innovations, thanks to the SBIR Advance program’s latest round of funding. Seven businesses, selected for Phase I, will receive up to $75,000 each, and one Phase II business will receive up to $100,000.

The US Department of Energy has awarded CompRex a $148,810 Small Business Innovation Research (SBIR) grant for a Phase I project to investigate the potential for a single-step energy efficient process to remove organic contaminants and inorganic solids from water that comes out of the fracking gas/oil wells.

Eight small high-tech businesses in Wisconsin will receive up to $75,000 each to commercialize their innovations, thanks to the SBIR Advance program’s latest round of funding.

The state matching grant program provides assistance to companies in the process of completing a project in the federal Small Business Innovation Research (SBIR) or Small Business Technology Transfer (STTR) programs. This is the 10th round of SBIR Advance funding since this collaboration by the Wisconsin Economic Development Corporation (WEDC) and the University of Wisconsin-Extension’s Center for Technology Commercialization (CTC) began in 2014.

The U.S. Department of Energy granted CompRex, LLC a $150,000 Phase I grant to develop the manufacturing process for commercial scale compact heat exchangers needed for next generation power plants.

Recently, the Naval Nuclear Laboratory completed the initial thermal-hydraulic performance testing of a CompRex heat exchanger and provided test results to CompRex. The test results exceeded the expected design performance and provide additional proof that the CompRex design and construction methods are suitable for producing commercial size heat exchangers for supercritical CO2 service.

In August 2014 CompRex LLC (De Pere, Wisconsin) was awarded a contract to design, engineer, fabricate and test high pressure, diffusion bonded stainless steel heat exchanger for CO2 power cycle development. Today CompRex announces that they have passes a significant mile stone with the successful hydraulic pressure test of a fabrication demonstration unit representing the intended heat exchanger. A representative scaled-down unit was manufactured for pressure testing. Test results showed that the unit exceeded the expected burst pressure for the design.